Battery pack / fuel cell / e-Powertrain

DC source/sink

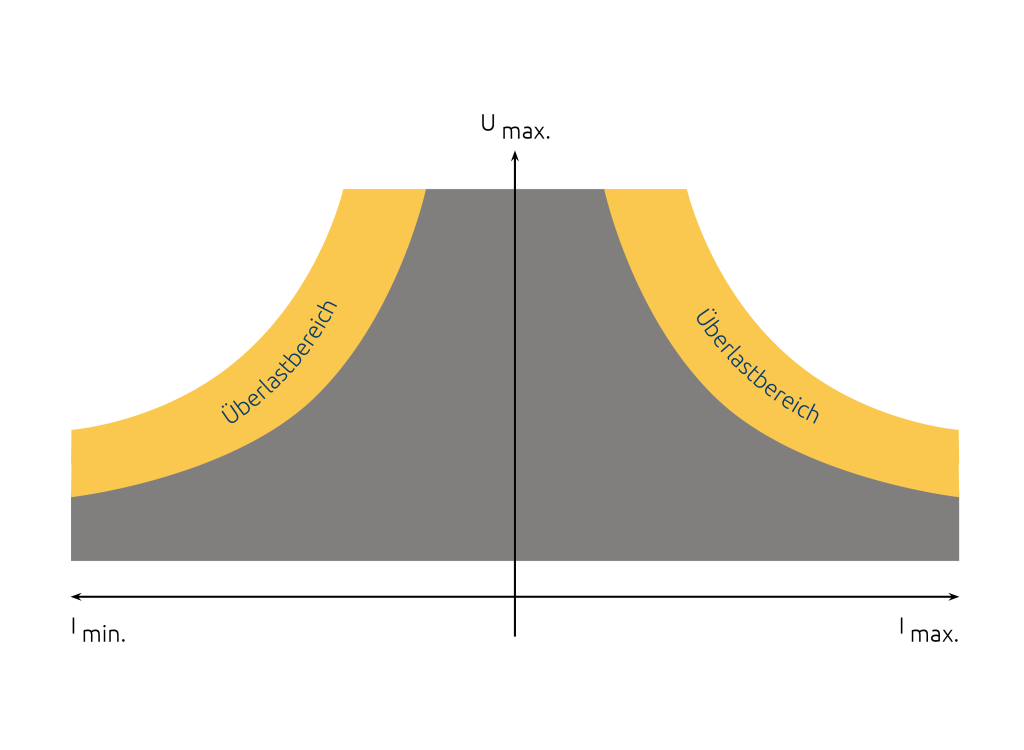

Single-Channel System – overload

I-TS-3870-ol: Single-channel system for testing and simulating batteries, fuel cells and powertrains. One output with up to 1500 V and 1200 A. Maximum power in single operation 650 kW, up to 2.6 MW in parallel operation. (Maximum values for voltage, current and power depending on the specific configuration).

Our high-performance test system I-TS-overload (Infeed test system – overload) is a high dynamic, bidirectional DC power supply with continuous and seamless transition from source to sink operation. The outstanding performance is the basis for a wide range of applications in the automotive,

hydrogen and laboratory sectors.

The I-TS-3870 overload version of our Infeed test system enables a short-term overload at the DC output. This means that certain operating points outside the nominal range can be approached and thus requirements in the test sequence can be fulfi lled by the I-TS.

The technical data of the DC converter in terms of output voltage and output current remain unchanged. However, up to 50 % higher rated output load is available for a maximum of 60 s.

The subsequent regeneration time (≤ nominal load) is 5 times the overload time.

Standard features

- The I-TS-3870-ol (overload) impresses even in the standard system configuration with its extensive

equipment and is therefore ready for immediate use by customers from all over the world. The following is a small excerpt:

General information - Input voltage 380 / 400 V, 50 / 60 Hz

- Sense connections for voltage measurement / regulation

- DC current and voltage measurement with 0.1 % full scale accuracy

- Battery tester version

- Protection class IP20

- Noise-reduced design (vibration metals, fan control)

- Air cooling

Safety features

- Lockable main switch as load-break switch

- Safety control for Performance Level d in accordance with EN 60204-1 / ISO 13849-1

- Stop switch in cabinet door

- Voltmeter and indicator light in cabinet door

- Redundant DC output contactors

- Connection terminals for external „emergency stop“

- Connection terminals for external „stop“

- DC output electrically isolated from the AC mains (galvanic isolation)

Interfaces

- 10 inch display with touch operation

- Modbus / TCP interface

- CAN interface

- VNC interface

Options (extract)

- Security level

Increase to performance level e as a special option - Battery emulation version (increased output capacity)

Hardware and software adaptation for special applications

to improve voltage stability for battery emulation - Protective diode at the DC output

Switchable diode to protect the device under test in sink-only mode - Insulation monitoring

Protective device for monitoring the galvanic isolation of the DC output

- Parallel operation

Increase in available power for certain applications through master-slave operation - Interfaces

Large selection of various optional interfaces such as CAN high-speed (1 kHz), SCPI, EtherCAT, Profi bus, Profi net, analog, LabVIEW, Matlab/Simulink - DC output contactors with higher performance

DC output contactors with increased current capability are optionally available to increase the service life - Door contact switch, door locking device, special locking cylinder

Operator safety is our top priority, therefore additional safety equipment is available for our customers

- System cabinets in a special design

Rittal enclosures, special bases, enclosures on castors, special paint fi nishes, wire end marking. The I-TS can be adapted to a wide range of customer requirements and local conditions - NA protection with grid analysis measuring device for power generation systems (VDE-AR-N 4105, VDE-AR-N 4110)

Due to grid operarotor regulations, NA protection may be required to monitor the grid quality for the I-TS - Water cooling including increased protection class IP54

Water cooling of the system cabinets is available to minimize waste heat to the room or to reduce noise. This also increases the protection class of the I-TS

Typical applications

- Battery tests (charge and discharge tests of batteries)

- Battery simulation / battery emulation

- Load for fuel cells

- Test power supply for contactors, fuses and circuit breakers

- Test of DC motors (drive train)

- Testing of charging columns (comemso)

- Power supply to trains for maintenance purposes at the ICE (German high speed train) plants

Technical data

Type I-TS-3870-ol

AC mains voltage / | 380 / 400 / 440 / 480 / 690 V ± 10 %, |

Measurement accuracy | Voltage: 16 Bit ADC // Current: 16 Bit ADC |

Control accuracy | Voltage: 0,1 % fs // Current: 0,1 % fs |

Residual ripple | Voltage: ≤ 0.1 % eff. fs |

Voltage tolerance | Battery tester< 3% fs |

Short circuit performance | Short circuit proof: |

Permissible environmental conditions: | 1K21 / 1M11, +5 bis +40 °C |

Cooling method | Cooling method Enforced air cooling (IP20, IP21, IP23) // enforced water cooling (IP54) |

Safety of machinery - | EN ISO 13849-1 |

Safety of machinery | EN 60204-1 Exception: |

EMC Standards | EN 61000-2-4 Class 3 |

Available types

Type | I-TS-3870-600-ol | I-TS-3870-800-ol | I-TS-3870-1000-ol |

|---|---|---|---|

max. DC voltage in V | 600 | 800 | 1000 |

Power in kW | 60, 100, 160, 250, 320, 400 | 100, 160, 250, 320, 400 | 60, 100, 160, 250, 320, 400, 500 |

Current in A |

|

|

|

Current rise time at 0.5x UNenn 10 % - 90 % in ms | < 1,0 | < 1,0 | < 1,3 |

Subject to technical changes

We will be happy to check your requirements/

Brochure as PDF

Brochure 1200 V, 1200 A as PDF

Learn more!

You want to know more about our products? We will be happy to send you more information by e-mail!