In the manufacturing of power supply systems, there is no way around numerous function and safety tests. Gustav Klein, a specialist in power supply, has therefore developed a new future-proof test field. For this, he relies on the modular safety solution from B&R. In this way, several test field configurations can be covered with just one software project.

Gustav Klein has a test field of around 500 square meters with a total of 13 test stations for large devices and additional test stations for small devices.

“Each of our systems is tested extensively before it is delivered,” explains Jörg Umbreit, Head of Development at Gustav Klein GmbH & Co. KG. “Due to the rapidly growing demand and increased performance requirements, we have increased our testing capacity from four to eleven test stations in autumn 2019 and increased the connected load of the test facility. Additional reserves have also already been planned for, as we expect further growth in the coming years.” Gustav Klein thus has a test field of around 500 square metres with a total of 13 test stations for large devices and further test stations for small devices.

Together with B&R, the company has developed a safety solution that covers all test stations, including the reserve and power distribution facilities. This is made possible by the modular design of B&R’s safety system, both on the hardware and software side. The safety functions for the test stations actually used can be easily selected or deselected via a configuration interface. The authorised staff member can select and confirm the configuration via the user interface. This means that no safety programming tool is required to change the configuration. Accordingly, it is easy to carry out conversions and maintenance work in the test bay or to commission the planned reserve.

With the new test bay, power supply specialist Gustav Klein is tripling its test capacity and now has one of the most modern and largest test facilities in the industry.

One safety project for all plant configurations

The highlight of the B&R approach: The safety application only needs to be tested and checked once in the maximum expansion stage. All conceivable combinations are already covered. This significantly reduces the maintenance effort for the software as well as the testing effort when commissioning modular systems or machines.

Gustav Klein recognised the advantages of this approach early on and has been using it successfully for some time now with its infeed test systems I-TS and MI-TS, which are completely automated with B&R technology. “With B&R’s Automation Studio development environment and the SafeDESIGNER integrated into it, we can cover 90 percent of our applications with just one safety software package without having to do any programming,” explains Umbreit.

The I-TS and MI-TS test and simulation systems are used in very different configurations as well as applications and environments. This includes, among other things, the simulation of battery behaviour for the development of battery-powered electric vehicles, including charging and discharging cycles, as well as the charging infrastructure and the testing of power supply components in battery and vehicle production.

Modularisation without special know-how

“The experience gained in these projects undoubtedly contributed to the fact that we were able to implement the safety application for the test field within a few days,” explains Roland Bayr, who as a software developer at Gustav Klein implemented the safety solution for the infeed tester and the test field. “But the simple connection of safe and non-safe areas as well as the fact that no special know-how or special procedure is required for the modularisation of the software with the B&R safety solution have also accelerated the work. Modularisation is an integral part without any additional effort or cost.” This was not insignificant for those responsible at Gustav Klein, as no turnover is generated directly with the development and construction of the test field and the safety application was to be realised parallel to the daily business.

Extensive safety technology

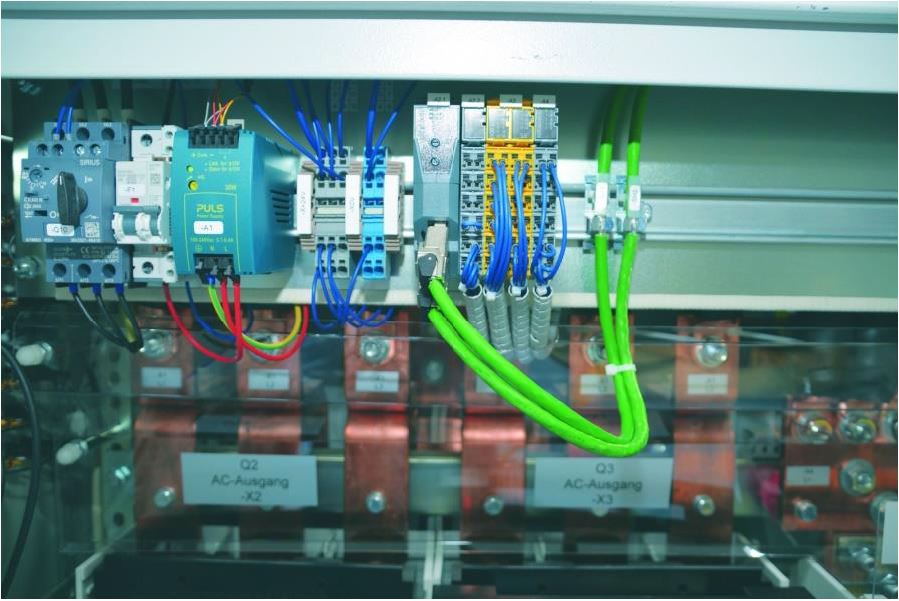

The planners at Gustav Klein chose various B&R components from the X20 series for the test field. Thus, safe digital input and output modules as well as mixing modules were installed in the test field and the connection units for the control and actuation of the safety-relevant sensors and actuators. A device of the type X20SL8101 from the X20 system functions as the safety controller. The control system is able to manage up to 280 safe nodes, the so-called SafeNODEs. In addition, the control also manages the optional safety devices such as the various test field configurations. The safe modules are connected to the safety controller via a standard cable and POWERLINK. Data communication is carried out using the openSAFETY safety protocol.

Much appreciated by the engineers at Gustav Klein: Safe and non-safe components can be lined up directly and work hand in hand at B&R.

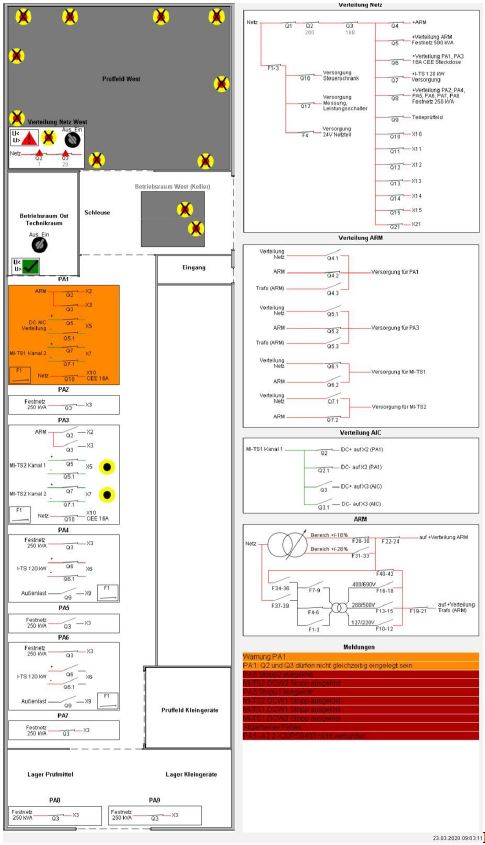

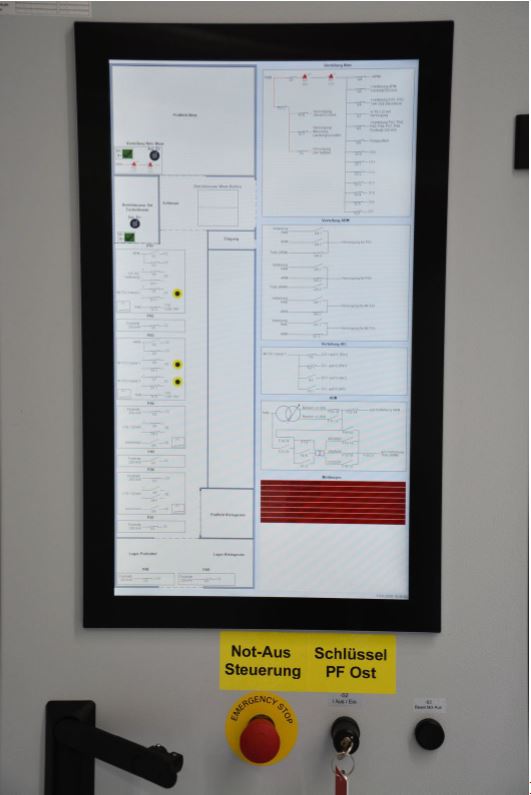

Complete test field at a glance

So that staff can quickly get an overview of the safety status and switching state

of the test field, Gustav Klein has developed a 24-inch device from the Automation

Panel 900 integrated into the door of the control cabinet in the operating room. On its back is

a space-saving Panel PC 2100 is mounted as a platform for the visualisation application.

The visualisation serves to inform the employees in the test field. “The large display

enables us to clearly show the status of the test field’s central circuits in their entirety

on just one screen page,” explains Bayr. “In this way, we avoid

events being lost from view because the operator is somewhere else

in some sub-menu. The arrangement on the screen also corresponds to that of the test field and

thus facilitates the localisation of the problem during an emergency event.”

In the near future, it is planned to place additional B&R displays in the test bay, which will

mirror the display in the operating room so that the inspectors can see the contents at all times.

Future-proof and flexible test laboratory

Since the expansion, the test laboratory of the specialist for power supply systems has been geared towards testing UPS systems and inverters with system outputs of up to 1.5 MVA. High-power tests and simulation systems with a nominal voltage of up to 1,000 V DC or AC as well as intelligent power electronics for high-performance energy storage systems with a system output of up to 4 MW can also be carried out there. The engineers succeeded in minimising the power consumption and thus the heat losses during test runs as well as the required mains connection power by intelligently networking the power electronics. This gives Gustav Klein one of the most modern and comprehensive testing facilities of its kind in the industry. This results in a significant advantage for the company’s customers: Gustav Klein now carries out high-performance tests at the factory, saving its customers a lot of valuable time when commissioning the systems on site. The modular safety solution from B&R allows the system manufacturer to flexibly adapt the safety technology to the requirements of the test field with reduced maintenance and thus react more quickly to changing market demands.

Jörg Umbreit

Head of Development, Gustav Klein GmbH & Co. KG

“With B&R’s Automation Studio development environment and the SafeDESIGNER integrated into it, we can cover 90 percent of our use cases with just one safety software without having to do any programming.”